Desalination membrane process

Fresh water is a limited resource on the earth while seawater is abundant yet unsuitable in various industries like food, chemical and pharmaceutical industries. Therefore, seawater desalination is the best way to solving freshwater shortage. In most cases, advanced desalination technology applied to seawater and brackish water has proven to be an effective way to solve the problem of freshwater scarcity.

Desalination refers to the process that removes excessive salts and minerals from saline water, or the chemical process that turns seawater into drinking water. This process can be used for all municipal, industrial or commercial purposes.

Generally, there are two processes for seawater desalination. One is thermal desalination, also known as distillation, as it desalinates seawater and turn it into drinking water through distillation. As it costs too much, it is rarely used. The other one is the most popular and economical membrane technology.

Desalination membrane process:

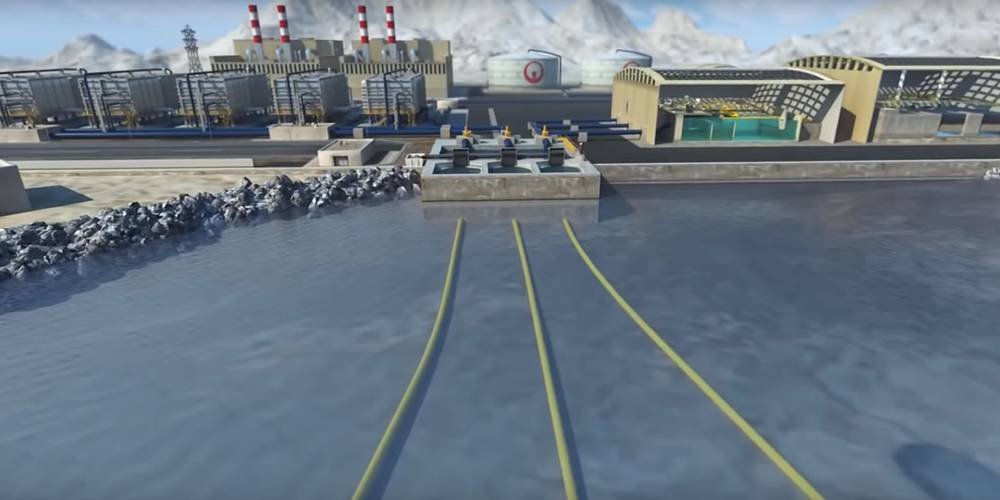

Flocculation and sedimentation pond. Seawater is pumped into the flocculation and sedimentation pond with a seawater pump. Coagulants are added into the pond for chlorine treatment and acid treatment.

Clean-water pond. The water in the flocculation and sedimentation pond flows into the V-type filter tank and clear-water pond after removing debris with gratings.

Self-cleaning filter. It consists of multimedia filter, activated carbon filter, water softener and ultrafilter (cartridge filter).

Ultrafiltration membrane system. Hollow fiber membranes are the main elements of the system.

RO reverse osmosis system. It consist of spiral-wound membranes and a FRP membrane housing.

Reverse osmosis membrane is a kind of artificial semi-permeable membrane with certain characteristics made of simulated biological semi-permeable membrane. It is the core component of reverse osmosis technology. The principle of reverse osmosis technology is that under the action of the applied pressure higher than the solution osmotic pressure, only water can pass through the semi-permeable membrane, thereby removing other substances from water. The pore size of the reverse osmosis membrane is very small, so that it can effectively remove dissolved salts, colloids, microorganisms and organic matter from water.

Reverse osmosis water tank. Generally, reverse osmosis water tanks are stainless steel water tanks or FRP water tanks.