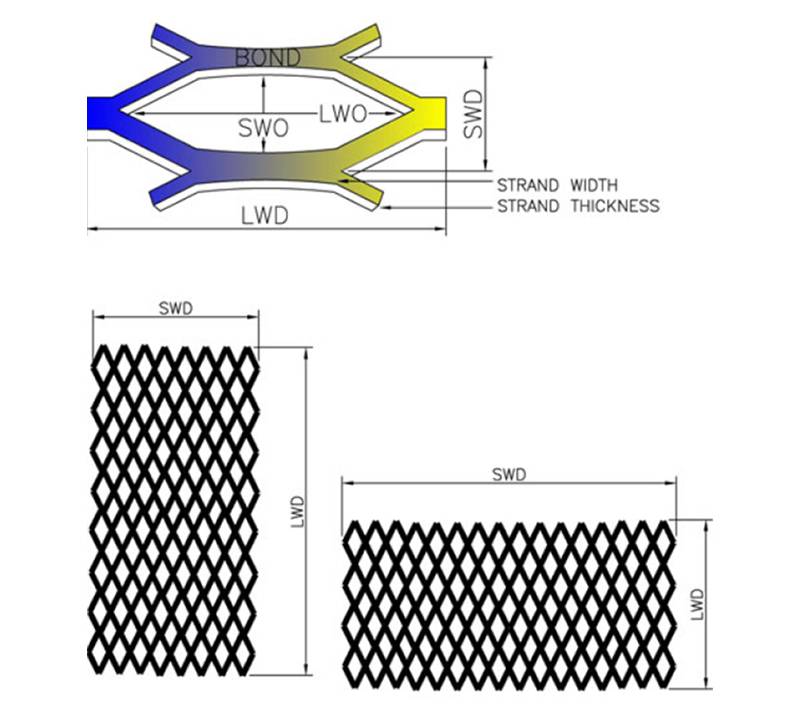

Expanded metal drawing with main term acronym label.

We’d like to list the abbreviations and related explanations of about expanded metal in a form as following.

| Abbreviation of Terminology | Explanation |

|---|---|

| SWD (Short Way Dimension) |

The length of short diamond diagonal from one pitch point center to another pitch point center. |

| LWD (Long Way Dimension) |

The length of long diamond diagonal from one pitch point center to another pitch point center. |

| SWO (Short Way Opening) |

The length of short diamond diagonal. |

| LWO (Long Way Opening) |

The length of long diamond diagonal. |

| Bond |

The solid intersection of two strands. |

| Pitch |

Another term for SWD. |

| Strand Width |

he length fed between the upper and lower tooling to produce the mesh. T |

| Strand Thickness |

Thickness of the metal that to be expanded.It is also the thickness of the material after flattening. |

| Burr |

An edge on the inside of the mesh that may be sharp or serrated in appearance. Caused by improper clearance or worn tooling. |

| Whisker |

An edge at the cut off of an expanded sheet or coil that looks like prongs in the shape of the mesh. Caused by a wide clearance, removal is done by wire brush or file at the expand work center. |

| Abbreviation of Terminology | Explanation |

|---|---|

| XM |

Raised or standard material in its original form coming off the expand work center. |

| FXM |

The result of passing (feeding) the standard material through a cold roll reducing mill to a defined specification that produces a uniform thickness of the entire sheet.The material elongates parallel to the feed direction creating a longer sheet in the feed direction and may reduce the size of the of the sheet opposite of the feed direction.

|

| Semi-Flat |

The result of passing (feeding) the standard material through a cold roll reducing mill to a defined specification that produces a less than uniform thickness of the entire sheet.The product is not flat by definition but somewhere between standard and flat. |

| Touch Pass |

The result of passing (feeding) the standard material through a cold roll reducing mill to slightly knock down the Bond. |

| XS |

Shorts, expanded material to be flattened. |

| SWM (Short Way Mesh) |

The dimensional (US/Metric) size parallel to the SWO of the sheet or coil. |

| LWM (Long Way Mesh) |

The dimensional (US/Metric) size parallel to the SWO of the sheet or coil. |

| Crow’s Feet |

This can be result of improper manufacturing and/or incorrect raw material length. These are open bonds that resemble a crow’s foot. |

| Abbreviation of Terminology | Explanation |

|---|---|

| M/R (Machine Run) |

Expanded metal mesh or walkway grating as it comes off the expander. |

| Random Sheared |

R/S, expanded metal mesh or walkway grating that is sheared or cut to a defined size without specific requirements. Sheet size can be held to tight tolerance. Likely to have open meshes. |

| Bond Sheared |

B/S, expanded metal mesh or walkway grating that is sheared or cut to a defined size on the bond or knuckle.Sheet size is dependent on where the bond falls during the M/R process. Produces closed meshes. |

| Balance Bond Shear |

BB/S, an older term not much used, expanded metal mesh or walkway grating that is sheared or cut to a defined size along a center line on the bond or knuckle.Sheet size is dependent on where the bond falls during the M/R process. Produces closed uniform meshes.This process can be achieved through a M/R expand. |

| Mesh Blank |

The amount of raw material being fed into the expander to make an expanded finished length. |

| Blank |

The combined total amount(s) of the mesh blanks being fed into the expander. |

| Hold Down |

The amount of raw material not expanded during the expand process.It is important to keep this to a minimum, the dimension varies for each expand work center. |

| Drop |

Another term for hold down. |

| Trim Cut |

The amount of raw material used to square the raw material prior to the expand process. In a sheet feed operation, this is done at every new sheet.It is required this be kept at four strokes. |

| Line Out |

The final process of expand work center set-up that finalizes specifications before the work-order begins. |

| Camber |

The greatest deviation of a side–edge, from a straight line. Parallel to the LWD, touching both ends of the sheet.It is natural for expanded materials to have this condition as it comes off the press. |

| Out Of Square |

The condition of not having 90 degree angles on the corners of the sheet also measured by placing a straight edge, parallel to the SWM.This is also natural for expanded materials to have this condition as it comes off the press. |

| Clearance |

The distance between the upper and lower tooling. It is measured with shims and is varied depending on the expand work center and material being expanded. |

| Tooling |

The forming and cutting materials used to produce expanded mesh. Upper tooling does the forming and comes in many shapes and sizes. Lower tooling is a flat surface that acts as a shear. The upper tool passes in front of the lower tool much like scissors to produce mesh. |